The potential of machine learning to understand the conversion of CO2

ICIQ researchers have developed a machine learning model to simulate and understand the materials for the conversion of CO2 to fuels and plastics, closing the carbon cycle.

Carbon dioxide (CO2) is among the most well-known greenhouse gases emitted. Reducing emissions of this gas is one of the primary strategies to combat climate change, but actions can also be taken regarding the emitted carbon dioxide. If this industrially produced CO2 is recovered and converted back, for example, into fuels, we can have a circular process that reduces the industry’s impact on the environment.

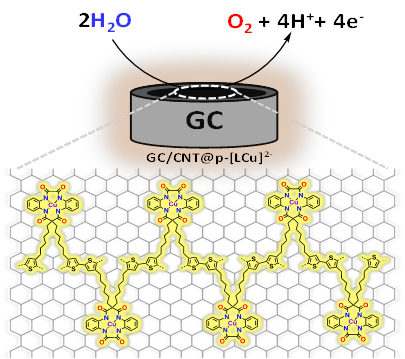

In more detail, closing the carbon cycle through electrochemical CO2 reduction (eCO2R) with renewable energy has drawn attention for its potential to create net-zero technologies. Concerning this reaction, catalysts based on copper (Cu) have shown the best performance for producing ethanol and ethylene, precursors of fuels and plastics. Catalysts based on Cu, and particularly oxide-derived Cu (OD-Cu) catalysts, exhibit unique performance that has been attributed to the singularities of its morphology.

The OD-Cu catalysts structure remains controversial due to its highly dynamic behaviour under experimental conditions. The real structure of the catalysts is hard to be captured by experimental characterization and traditional simulation technologies, and here is where advanced machine learning based simulation can play an important role.

In a recent paper published in Nature Catalysis, researchers from the Theoretical Heterogeneous Catalysis Group of Prof. Núria López at the Institute of Chemical Research of Catalonia (ICIQ-CERCA) have modelled the dynamic evolution of OD-Cu under different reaction conditions. This study gives insight into the mechanism of the reduction of OD-Cu to metallic Cu and the limits for its fine-tuning.

This work deepens the research community’s understanding on this fundamental topic and provides a solid foundation for the future development of efficient catalysts and optimization of reaction conditions to achieve net-zero emissions.

Explains Dr. Zan Lian, first author and co-corresponding author of the work and MSCA postdoctoral researcher from Prof. López group.

This work investigates the reduction process of OD-Cu performing large-scale molecular dynamics simulations and training a precise neural network potential (NNP) on these first-principles data. Then, they have employed this NNP to develop a dataset of almost 60.000 data points to address the highly dynamic nature of the catalysts, which is strongly coupled to its history and to the reaction conditions. Based on the simulations, the evolution of the OD-Cu structures under different conditions was defined as well as the distributions of the active sites for eCO2R, thus paving the way for their control.

The ICIQ computational researchers have analysed the stability of residual oxygen and its reduction kinetics and have compare it to the most recent experimental observations. The results show that in long electrochemical experiments, the catalyst would be fully reduced to Cu, yet removing all the trapped oxygen takes a considerable amount of time. Under air exposure instead, the oxygen atoms tend to aggregate on the surface to form Cu2O, while bulk diffusion and deep oxidation are initially prevented.

This study provides clear guidelines to experimentalists on how to treat OD-Cu to get the best CO2 reduction products.

Dr. Federico Dattila, co-author of the paper, is enthusiastic about the work

Reference paper

Lian, Z., Dattila, F. & López, N. Stability and lifetime of diffusion-trapped oxygen in oxide-derived copper CO2 reduction electrocatalysts. Nat Catal (2024). https://doi.org/10.1038/s41929-024-01132-5

Related news

Let's create a brighter future

Join our team to work with renowned researchers, tackle groundbreaking

projects and contribute to meaningful scientific advancements

11-12-2024

11-12-2024