Structure, Activity, and Deactivation Mechanisms in Double Metal Cyanide Catalysts for the Production of Polyols

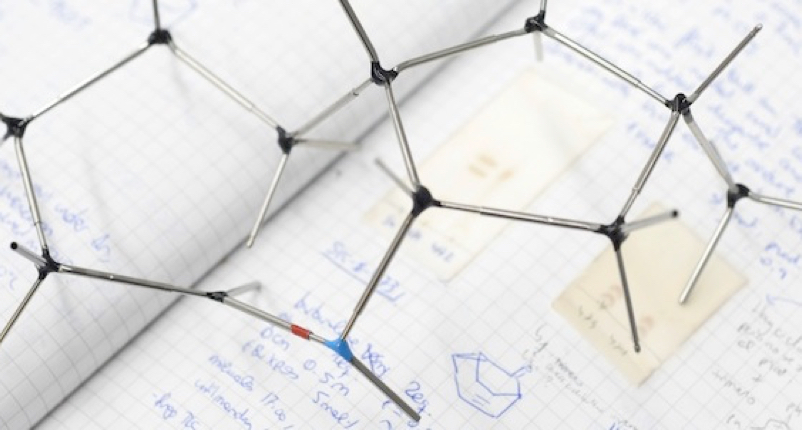

Polyether polyols are used widely in the plastic and coating industries in the form of polyurethanes. The polymerization of epoxides can be catalyzed by double metal cyanides (DMCs), Zn3[Co(CN)6]2. These catalysts were first reported in the 1960s by General Tire Inc. and provide products with excellent technical features, which are better than those that result from traditional alkaline polymerization as side reactions are alleviated. However, DMC-catalyzed polymerization is not free of drawbacks as high-molecular-weight side products (1–3 wt %) can form in the propylene process. These tails are detrimental to the subsequent use of these polymers, in particular to foam stability. Despite the wide industrial interest in DMCs, there are only a few experimental studies and a complete lack of theoretical research of their structure, activity, and performance. The present work is thus the first attempt to describe the nature of the active site, the main polymerization mechanism, and two potential origins for the high-weight tails from a theoretical standpoint by analyzing three crucial steps in the polymerization process.

N. Almora-Barrios, S. Pogodin, L. Bellarosa, M. García-Melchor, G. Revilla-López, M. García-Ratés, A. B. Vázquez-García, P. Hernández-Ariznavarreta, N. López

ChemCatChem 2015, 7, 928-935

DOI:

Go to the journal

Let's create a brighter future

Join our team to work with renowned researchers, tackle groundbreaking

projects and contribute to meaningful scientific advancements