Glycerol oxidehydration to pyruvaldehyde over silver-based catalysts for improved lactic acid production

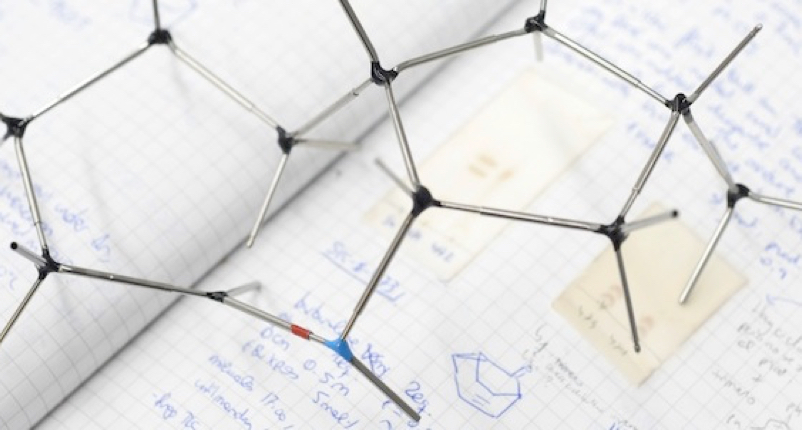

Sustainable technologies for the valorisation of the burgeoning amounts of glycerol (GLY) obtained as waste in the production of biodiesel are increasingly sought after. Its conversion into lactic acid (LA) is highly appealing due to the versatility of this platform chemical and its high added value. Here, we introduce Ag-based catalysts for the oxidehydration of GLY to pyruvaldehyde (PAl) and demonstrate the superiority of this compound in comparison to dihydroxyacetone (DHA) as the intermediate of an alternative two-step GLY-to-LA process. Evaluation of various metals and carriers identified Ag/Al2O3 as the best performer for PAl production. This was rationalised based on the optimal redox potential of the metal and the high concentration of Lewis-acid sites and the limited Brønsted acidity of the support. Tuning of the temperature and oxygen feed concentration enabled to boost the PAl yield (80%) and attain stable operation in a 24-h run. Characterisation of the used catalyst indicated that the surface of the silver nanoparticles was partially oxidised upon reaction. Density functional theory modelling revealed that the oxidation of acetol obtained from GLY after the initial dehydration is kinetically and thermodynamically favoured on a partially oxidised silver surface (AgOx/Ag) compared to metallic (Ag) or fully oxidic (Ag2O) ones. Finally, we show that PAl can be isomerised into LA and methyl lactate over Sn-containing zeolites with the same rates as DHA but at a 40 K lower temperature (343 vs. 383 K). This not only allows for energy savings but also for a remarkably increased stability of the stannosilicates.

G. Marco Lari, R. García-Muelas, C. Mondelli, N. López, J. Pérez-Ramírez

Green Chem. 2016, In press DOI: 10.1039/C6GC00894A

DOI:

Go to the journal

Let's create a brighter future

Join our team to work with renowned researchers, tackle groundbreaking

projects and contribute to meaningful scientific advancements