Flame-made amorphous solid acids with tunable acidity for the aqueous conversion of glucose to levulinic acid

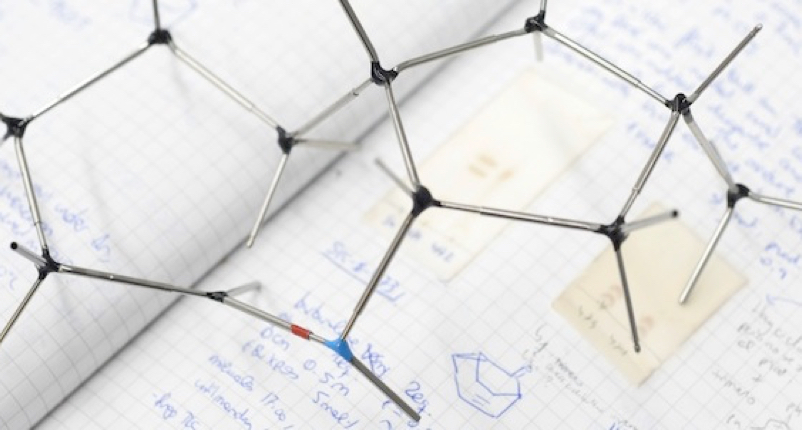

Solid acids of amorphous silica-alumina (a-SA) and amorphous silica-alumina-phosphate (a-SAPO) were prepared by flame spray pyrolysis (FSP). Careful tuning of the acidity of the solid acids was enabled by capitalizing on the advantage of FSP in preserving the metal stoichiometry (i.e., Si, Al, P) in the product nanoparticles. Although the amount of acids on these non-porous solid acids is an order of magnitude lower than the well-recognized strong acidic ZSM-5 zeolite, both exhibit comparable acid strengths. The a-SA and a-SAPO were characterized by a mixture of Brønsted (B) and Lewis (L) acids, and the B/L ratios were composition-tunable. The highest B/L ratios were recorded for a-SA (Al/(Al + Si) = 0.4) and a-SAPO (Si/(P + Si) = 0.25), giving the highest yields of levulinic acid (≥40% carbon yield) from the conversion of glucose in the aqueous phase without requiring the addition of liquid acids or metal halides. Under the same conditions, the almost exclusive Brønsted acid ZSM-5 yielded only 17% levulinic acid. The FSP-made solid acid catalyst exhibited good reusability over at least 4 consecutive runs.

Khai Beh, G.; Ting Wang, C.; Kim, K.; Qu, J.; Cairney, J.; Hau Ng, Y.; Kyoungjin An, A.; Ryoo, R.; Urakawa, A.; Yang Teoh, W.

Green Chem. 2020, 2020, (22), 688-698

DOI:

10.1039/C9GC02567G

Let's create a brighter future

Join our team to work with renowned researchers, tackle groundbreaking

projects and contribute to meaningful scientific advancements