Catalyst Engineering Empowers the Creation of Biomass-Derived Polyesters and Polycarbonates

The introduction of circular principles in chemical manufacturing will drastically change the way everyday plastics are produced, thereby affecting several aspects of the respective value chains in terms of raw feedstock, recyclability, and cost. The ultimate aim is to ensure a paradigm shift toward plastic-based (consumer) materials that overall can offer a more attractive and sustainable carbon footprint, which is an important requisite from a societal, political, and eventually economical point of view. To realize this important milestone, it is vitally important to control the polymerization processes associated with the creation of novel sustainable materials. In this respect, we realized that expanding the portfolio of biomass-derived monomers may indeed create an impetus for atom circularity; however, the often sterically congested nature of biomass-derived monomers minimizes the ability of previously developed catalysts to activate and transform these precursors. Our motivation was thus spurred by an apparent lack of catalysts suitable for addressing the conversion of such biomonomers, as we realized the potential that new catalytic processes could have to advance and contribute to the development of sustainable materials produced from polycarbonates and polyesters. These two classes of polymers represent crucial ingredients of important and large-scale consumer products and are therefore ideal fits for implementing new catalytic protocols that enable a gradual transition to plastic materials with an improved carbon footprint.

Brandolese, A.; Kleij, A. W.

Acc. Chem. Res. 2022

DOI:

10.1021/acs.accounts.2c00204

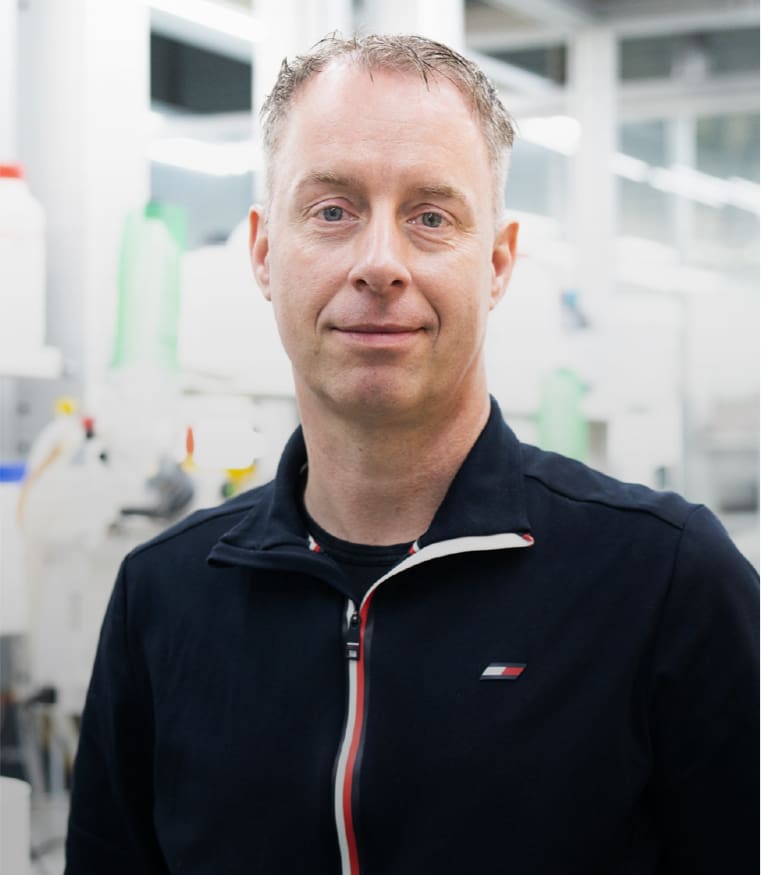

Let's create a brighter future

Join our team to work with renowned researchers, tackle groundbreaking

projects and contribute to meaningful scientific advancements