Printing a 3D structure with a photocatalyst incorporated: A way to improve its photocatalytic performance and reusability

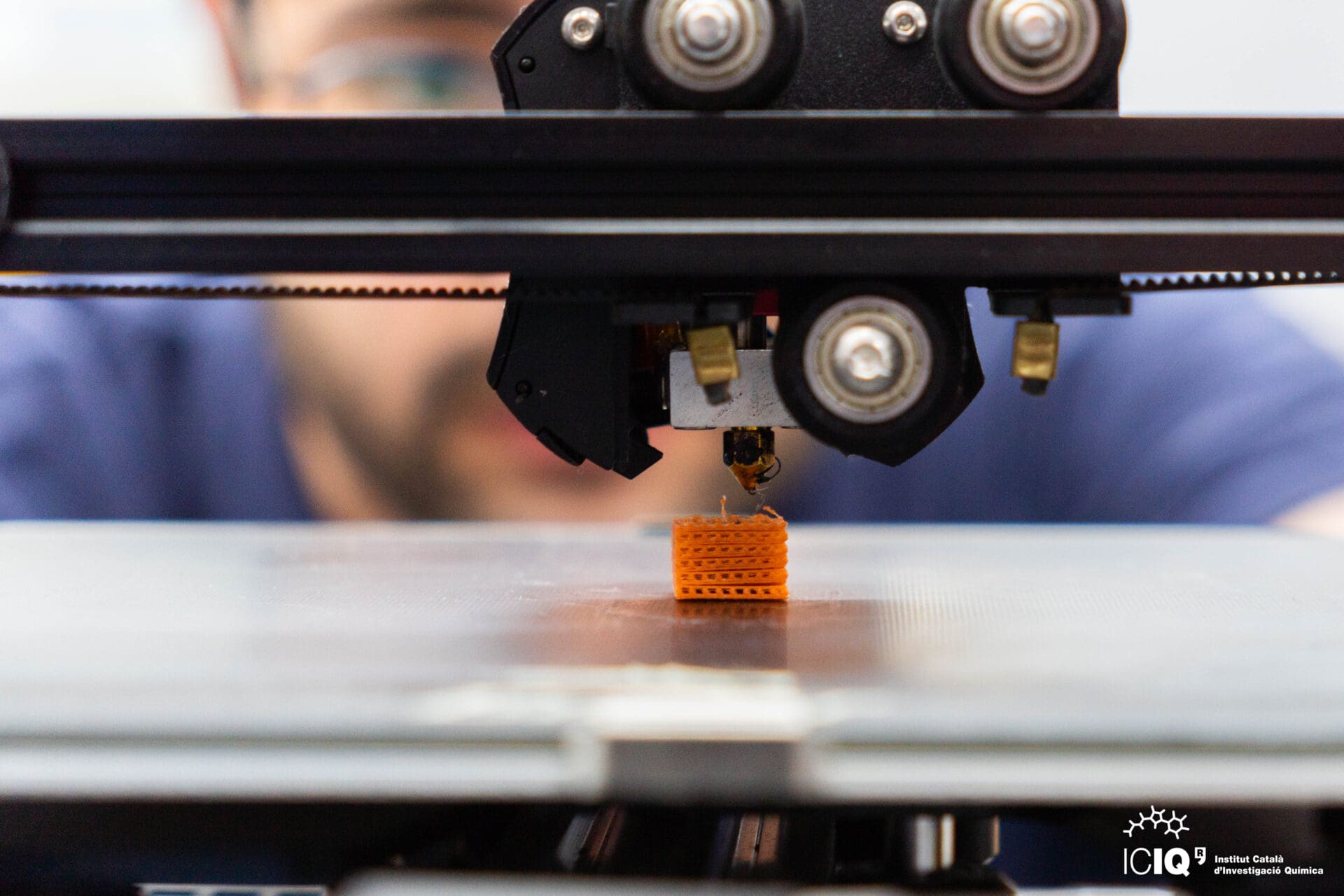

The Fused Deposition Modelling (FDM) technique allowed the printing of a structure with a photocatalyst added to the polymer filament

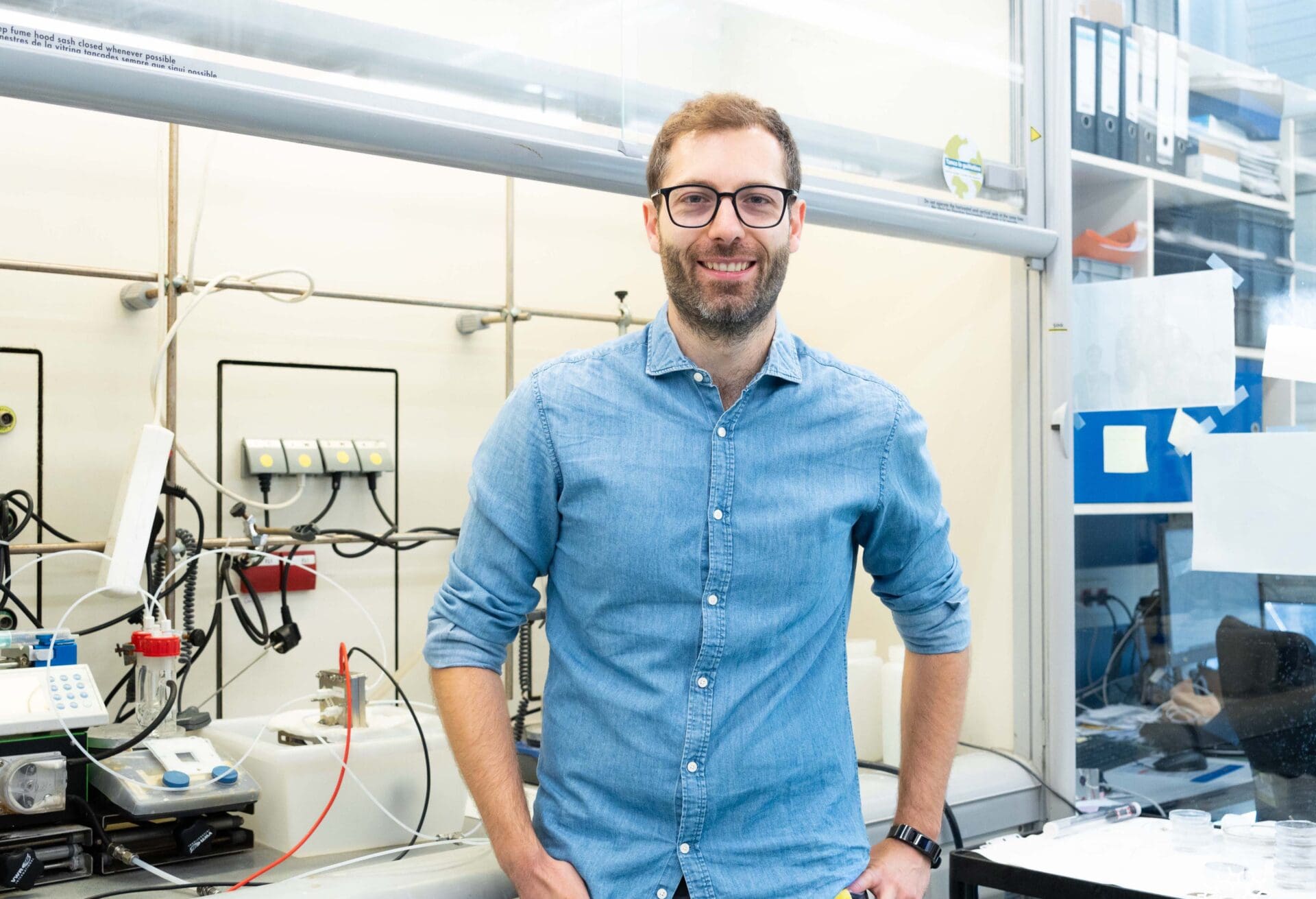

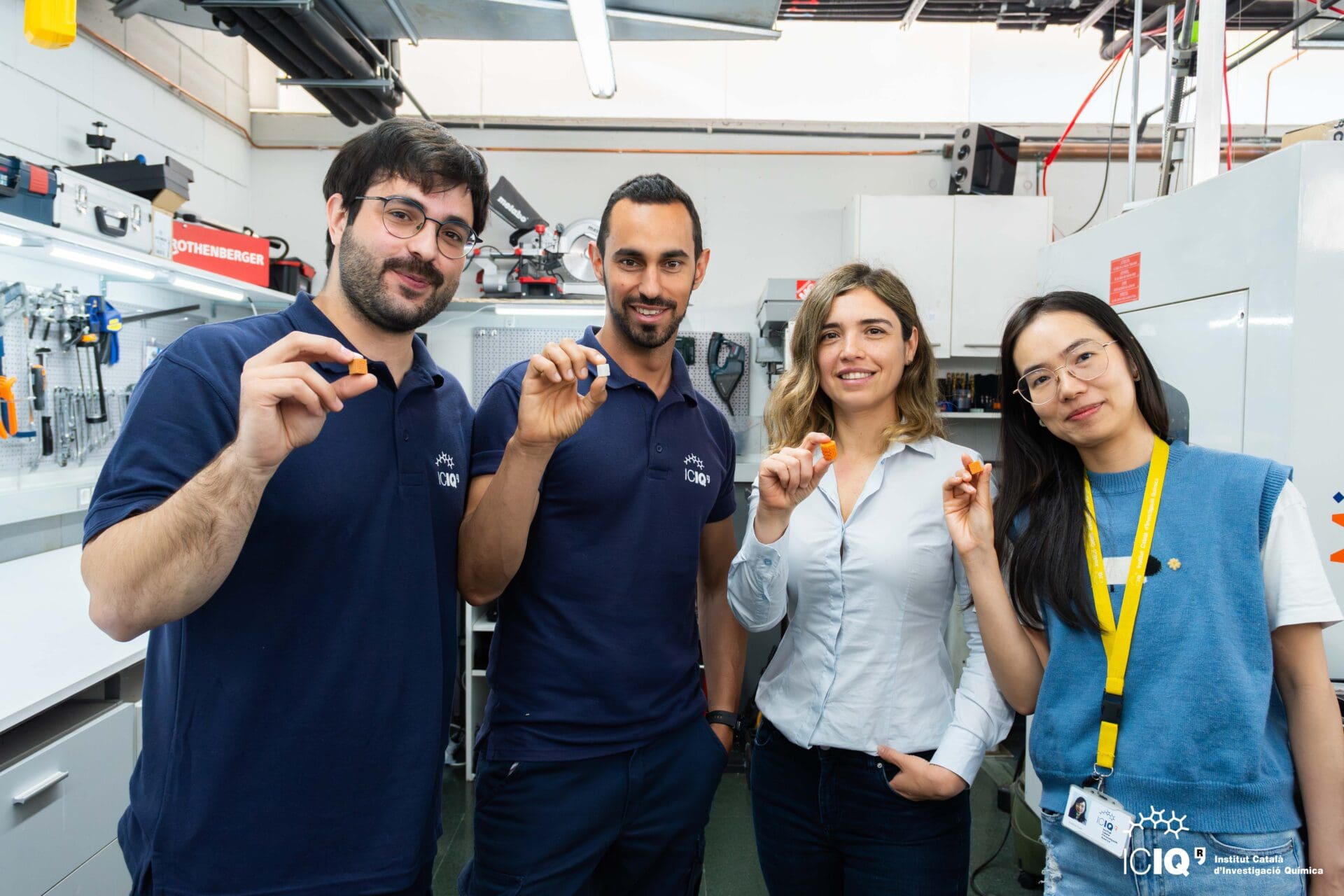

The Mechanical Workshop at the Institute of Chemical Research of Catalonia (ICIQ-CERCA), along with Dr. Katherine Villa’s group, have created a 3D-printed structure with a catalyst added to the polymer, which improves its photocatalytic properties.

Small molecule organic semiconductors (SMOSs) have emerged as a new class of photocatalysts that exhibit visible light absorption, tunable bandgap, good dispersion, and solubility. However, the recovery and reusability of such SMOSs in consecutive photocatalytic reactions is challenging. Dr. Katherine Villa envisioned the 3D printing technology as a solution to overcome the named drawbacks, and the solution emerged as a result of a collaboration between Dr. Villa’s research group and ICIQ Mechanical Workshop.

The solution proposed concerns a 3D-printed hierarchical porous structure based on an organic photocatalyst (SMOS). Upon manufacturing, the photophysical and chemical properties of the organic semiconductor were maintained and its performance as catalyst was enhanced, with longer lifetime and easier recovery.

The photocatalytic performance was tested for the degradation of organic pollutants and hydrogen production, showing competitive photocatalytic rates under sun-like irradiation.

This design enables, for the first time, the loading of an organic conjugated small molecule acting as a catalyst into a polymer with promising photocatalytic results. The Fused Deposition Modelling (FDM) technology allows the 3D printing of customised filaments, adding the desired molecule or additive into a polymer chosen among multiple options. In the present case, an organic photoactive molecule was added to ABS, a compatible polymer that acted as matrix. Moreover, FDM allows building multiple shapes and versatile structures.

FDM printing technology resulted the more convenient among other 3D printing techniques, as the optimal one to develop the project. SLS or Resin printing techniques, both involving a laser, may be too aggressive for the catalyst, while SLS also requires an extremely homogeneous nylon powder difficult to achieve adding any component to it.

The discovery, a collaboration between an ICIQ research group and the Scientific Core Facilities Mechanical Workshop that resulted in a success story, has been published in ChemSusChem Journal.

Related news

Let's create a brighter future

Join our team to work with renowned researchers, tackle groundbreaking

projects and contribute to meaningful scientific advancements

17-12-2024

17-12-2024