Nickel: a greener route to fatty acids

New nickel catalyst fuses unrefined hydrocarbons and CO2

to obtain valuable compounds

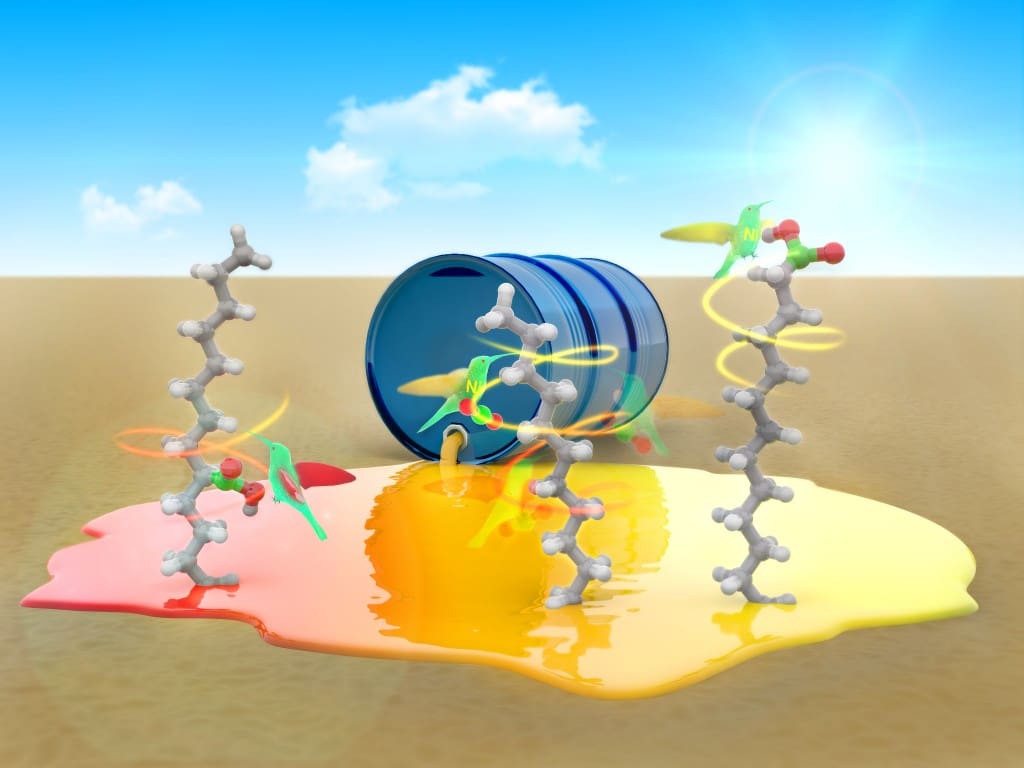

Chemists designed a nickel catalyst that easily transforms petroleum feedstocks into valuable compounds like fatty acids. The process is environmentally friendly: not only it works at room temperature and atmospheric pressure, but also recycles carbon dioxide, contributing to the fight against climate change.

Fatty acids are key in several industrial processes like the manufacture of soaps, plastics –such as nylon– and dyes. Experts estimate that the global market for these compounds could reach $20 billion in the next few years. Classical synthetic methods to obtain fatty acids often require toxic and hazardous reagents like carbon monoxide and extreme conditions of pressures and temperatures. Alternative methods like the derivatization of natural products are less dangerous, but lead to complicated mixtures of products that require tedious purifications. Now, a team led by Prof. Rubén Martín at the Institute of Chemical Research of Catalonia (ICIQ) synthesized a sustainable nickel catalyst that solves both problems. It leads to pure fatty acids from raw hydrocarbons and CO2, which is less toxic than carbon monoxide.

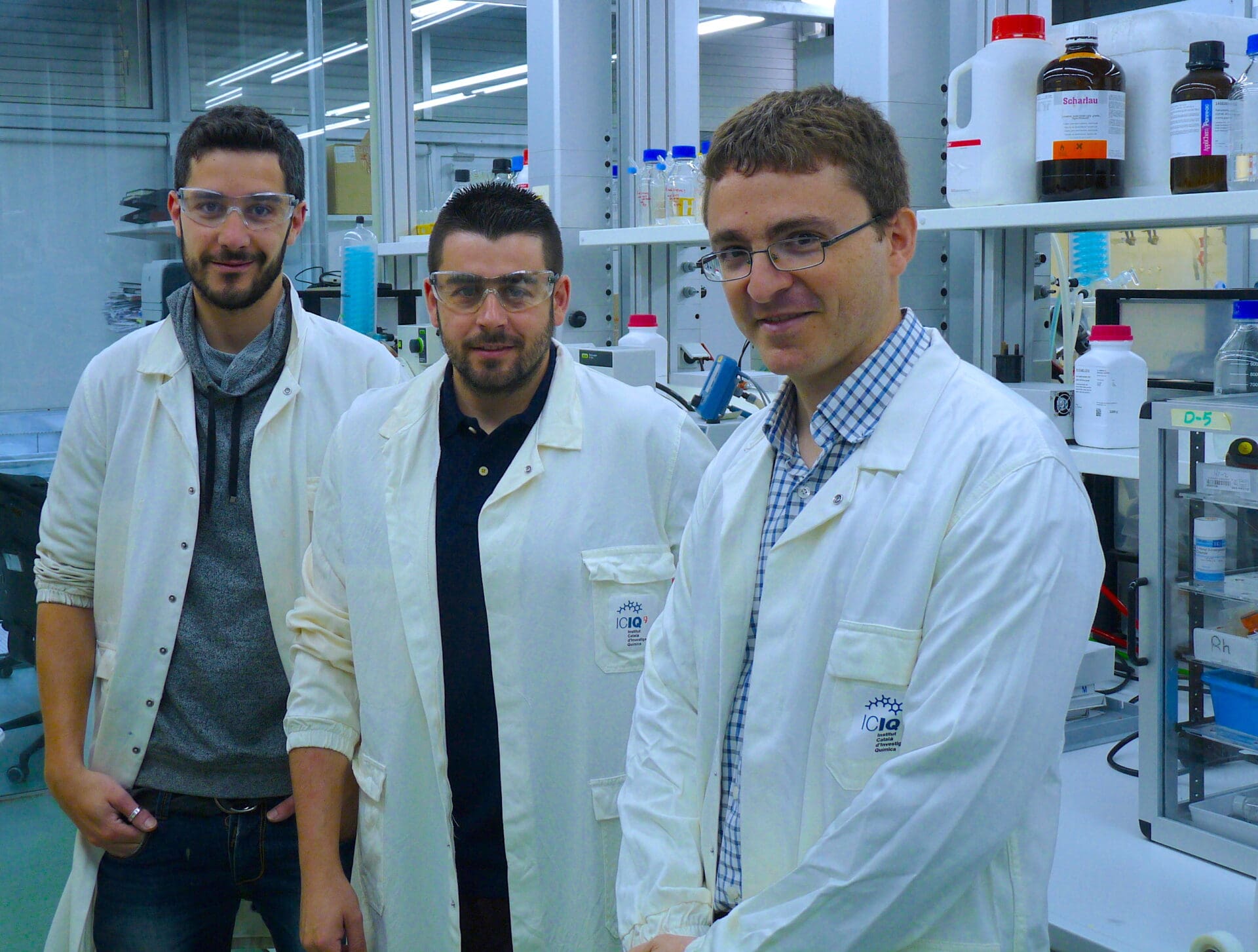

Toni Moragas, Francisco Juliá and Prof. Rubén Martín, part of the ICIQ team that carried out this research.

Unrefined mixtures of hydrocarbons, olefins, and other petroleum-derived feedstocks can now be easily transformed into fatty acids. Moreover, researchers discovered the selectivity of the reaction can be regulated with subtle temperature variations. Tuning temperature, nickel slides along the hydrocarbon chain, incorporating CO2 closer to the end of the chain when the conditions are colder, and vice-versa.

“This chemistry allows us to repurpose simple hydrocarbons and endless-available CO2 to prepare a wide range of pure fatty acids under exceptionally mild conditions,” explains Martín. “This method enables the selective incorporation of CO2 at specific sites while preserving the chiral integrity within the organic molecule,” he adds.

“The combination of an earth abundant nickel catalyst and CO2 with the hydrocarbon feedstocks is a breakthrough in the production of fatty acids,” explains Francisco Juliá, first author of the Nature paper. “Current methods rely on hazardous carbon monoxide and precious metal catalysts in high risk of supply disruption. This is a greener and more sustainable methodology that could have significant implications for the environment whilst alleviating economical concerns,” he concludes.

Martín’s team prepared several added value products of interest like nylon precursors and cholesterol derivatives. This innovative field of research was awarded a Proof of Concept Grant from the European Research Council in 2015. Also, ICIQ recently filed a European patent to protect the process and to be able to license it to chemical industries in the near future.

Remote Carboxylation of Halogenated Aliphatic Hydrocarbons with Carbon Dioxide.

F. Juliá-Hernández, T. Moragas, J. Cornella, R. Martin.

Nature, 2017, DOI: 10.1038/nature22316

Related news

Let's create a brighter future

Join our team to work with renowned researchers, tackle groundbreaking

projects and contribute to meaningful scientific advancements

12-12-2024

12-12-2024