ICIQ laboratories to promote the segregation of plastics for recycling

A portable infrared spectroscopy device granted by BASF allows to separate the clean plastic by type and at the origin of its generation

A clean plastic segregation project developed within the ICIQ laboratories was the winner of Plastic Waste Challenge organized by trinamiX GmbH, a subsidiary of BASF. The project submitted by the Safety, Health, Environment and Quality Department of ICIQ convinced the jury who positively assessed the current recycling challenges and awarded ICIQ with state-of-the-art device to facilitate process.

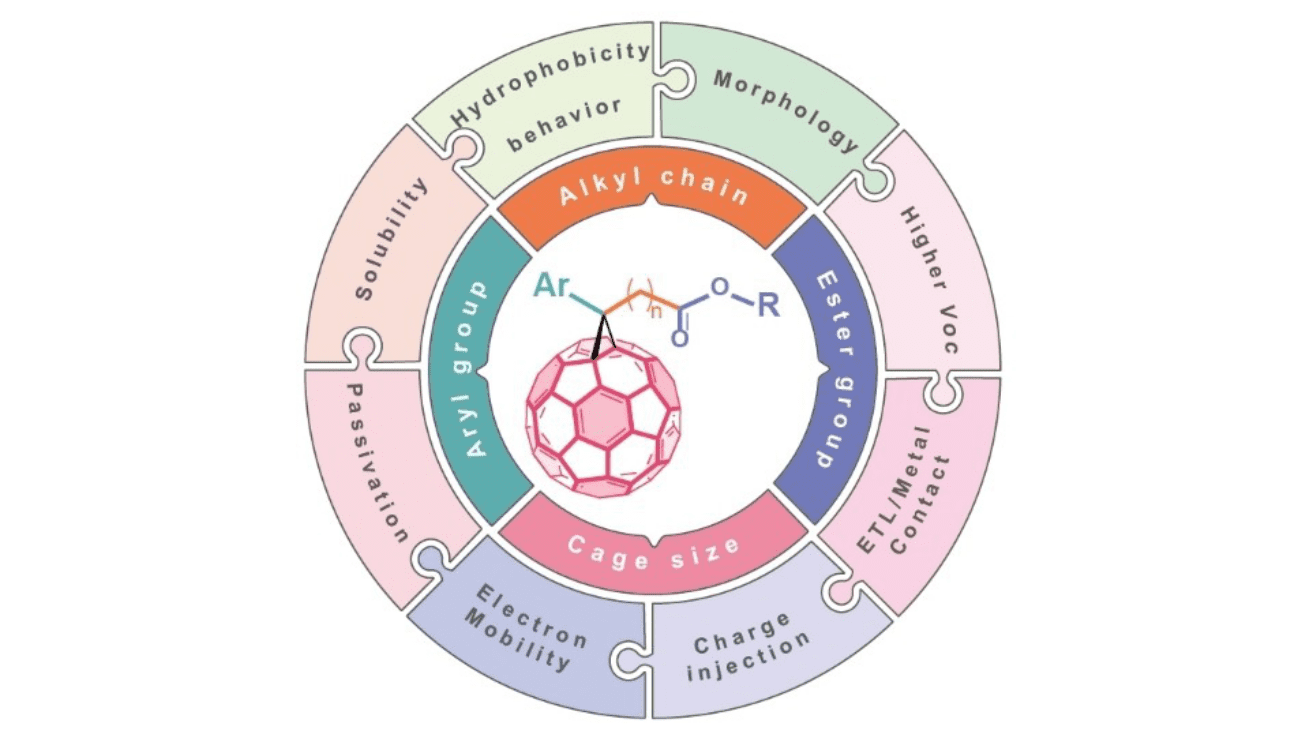

TrinamiX is a portable infrared spectroscopy device that allows to precisely identify the composition of plastics, facilitating their segregation and recycling. Separating plastics by type (PP, HDPE, LDPE, PS…) and by the origin of its generation is crucial to tackle today’s recycling challenges and therefore, the possibility of reusing the plastic.

“In January we started a pilot test at P1.5 Laboratory, which has allowed us to carry out an effective and precise separation of the uncontaminated plastic. The idea is to send the plastic for recycling, but also, we would like to be aware about the potential of each material we would have at the Institute in case we implement a segregation system for all ICIQ’s plastic”, explains Xavier Blanch, Manager of ICIQ’s Safety, Health, Environment and Quality Department.

In addition, ICIQ’s commitment is beyond the separation of plastic. In this sense, Blanch adds that “we are building a team of sustainability representatives, ECOReps, who will allow to integrate and develop the principles, guidelines and tackle environmental actions”. While, he emphasizes on the importance of “explore other alternatives regarding the temporary storage and transport of the plastic to the final recycling manager, evaluating the incorporation of compactors or other solutions that allow optimizing this process to minimize the impact environment of ICIQ”, reinforcing the sustainability strategy of the institute.

Related news

Let's create a brighter future

Join our team to work with renowned researchers, tackle groundbreaking

projects and contribute to meaningful scientific advancements

11-12-2024

11-12-2024