Creating and upgrading chemistry tools: the Mechanical and Glass Blowing ICIQ Workshops

Do you need a state-of-the-art photoreactor that is not available in the market? Could your devices be optimised to achieve a realoptimal procedure? Are you thinking about a new piece to complement your industrial development techniques?

There are two Workshops in the Institute of Catalan Research of Catalonia (ICIQ-CERCA) where everything can be produced to fit your experiment needs. The Mechanical and the Glass Blowing Workshops are two key elements of the ICIQ Core Facilities Area, but they don’t only give support to the ICIQ research groups, they are open to collaborate with companies and increase the competitiveness of the business or industrial sector.

The two units are specialized in the design and fabrication of a wide range of mechanical and glass pieces for very diverse applications, from chemical reactors to specific analytical samplers or building your own piece with your customized material. Companies can find these facilities helpful to improve their industrial technology processes.

The personnel in the Workshops have extensive expertise in their field, with over 10 years of experience in chemistry, as well as prior personal experience in glassblower and mechanics.

Pieces of aluminum, stainless steel or a wide range of polymers

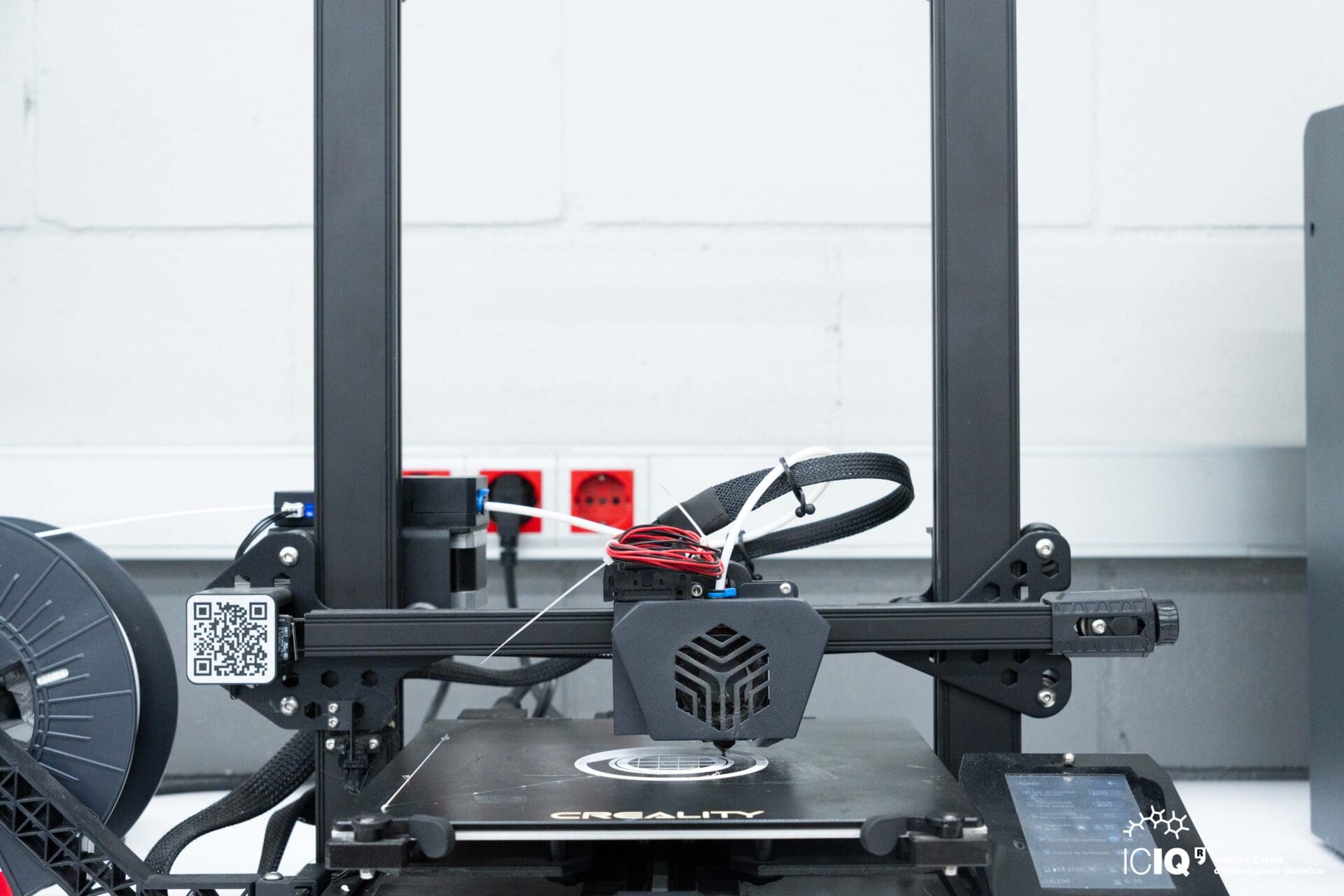

Customized reactors (including photoreactors), digital design, custom piece fabrication (either by mechanization or by 3D printing) or full setup of new devices. The expert personnel in the mechanical Workshop designs and fabricates a wide range of pieces. They can work with various materials, including aluminum, steel, Teflon, Nylon and other polymers.

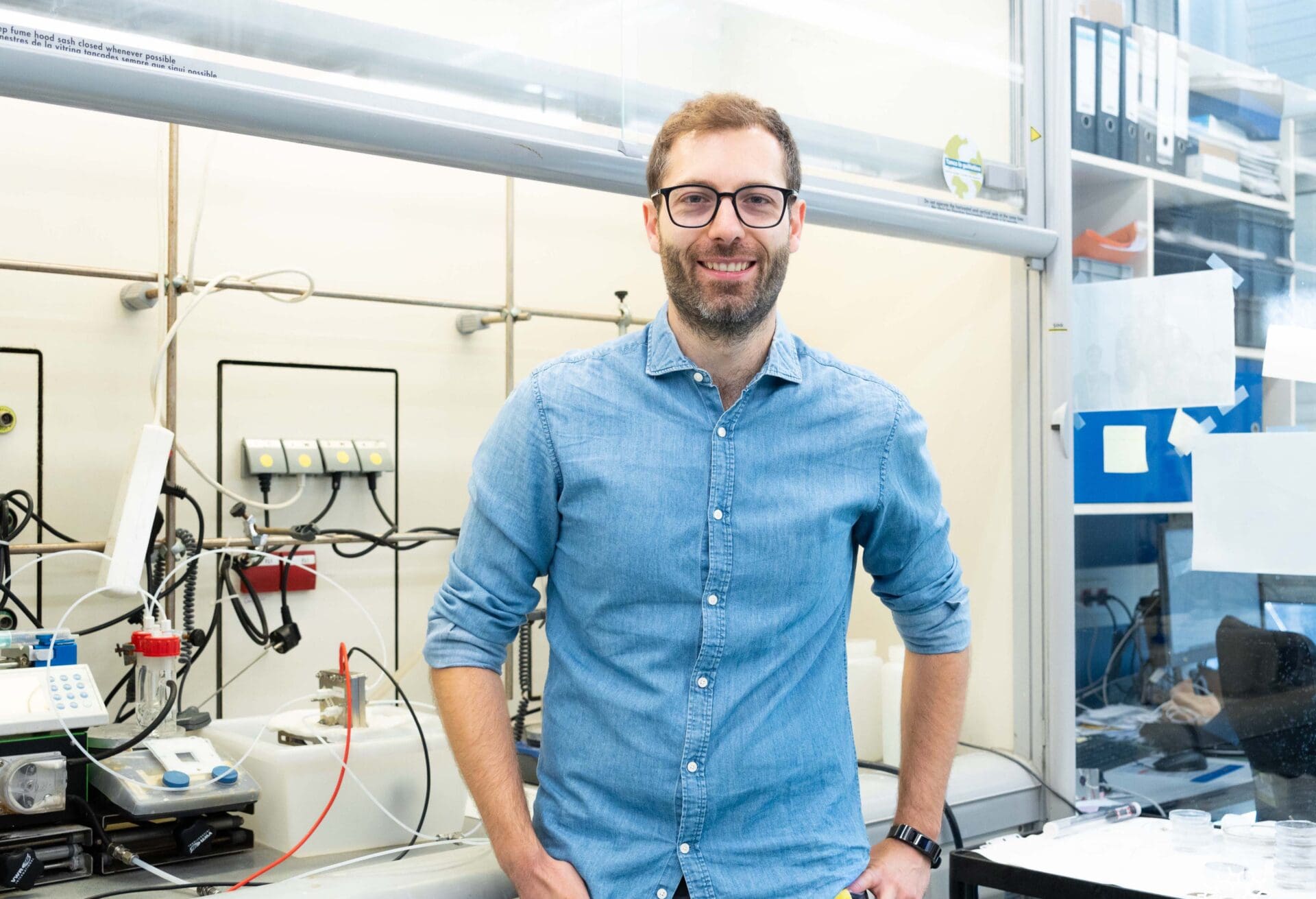

The team have developed technology for the tree ICIQ spin-offs: Orchestra Scientific, Trellum and Joltech Solutions. Their optimal pieces have been crucial for the success of these projects in the industry. The Mechanical Workshop is currently led by José Luís León and Aleix Terrado, who collaborate closely with project leaders: “We work hand by hand with researchers or project leaders to find and create solutions to their problems”, claims León, who also adds that “our job is all about creativity”. Nothing resists them.

The Workshop is equipped with 3D printers that allows them to work with a wide range of polymeric materials (thermoplastics or resins). It includes two milling machines and two lathes, as well as auxiliary tools such as saws, drills and polishers. The 3D Workshop has four 3D printers, two using FDM technology, one using resin photocuring technology and a third one that works by laser sintering (SLS). They have the capability to print with different materials, including PLA, ABS, PETG, NYLON and other special materialsincluding customized ones.

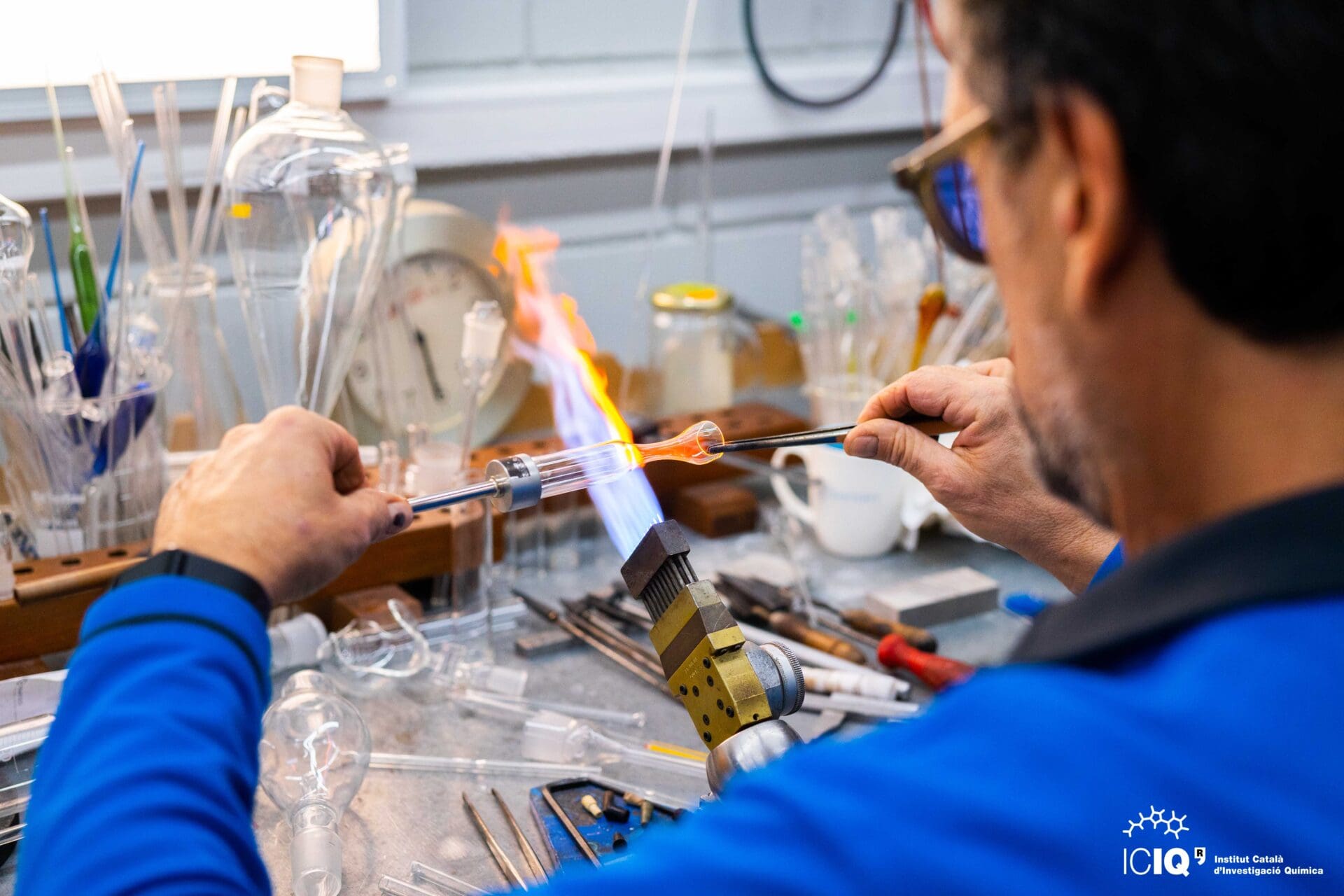

The art of glass blowing

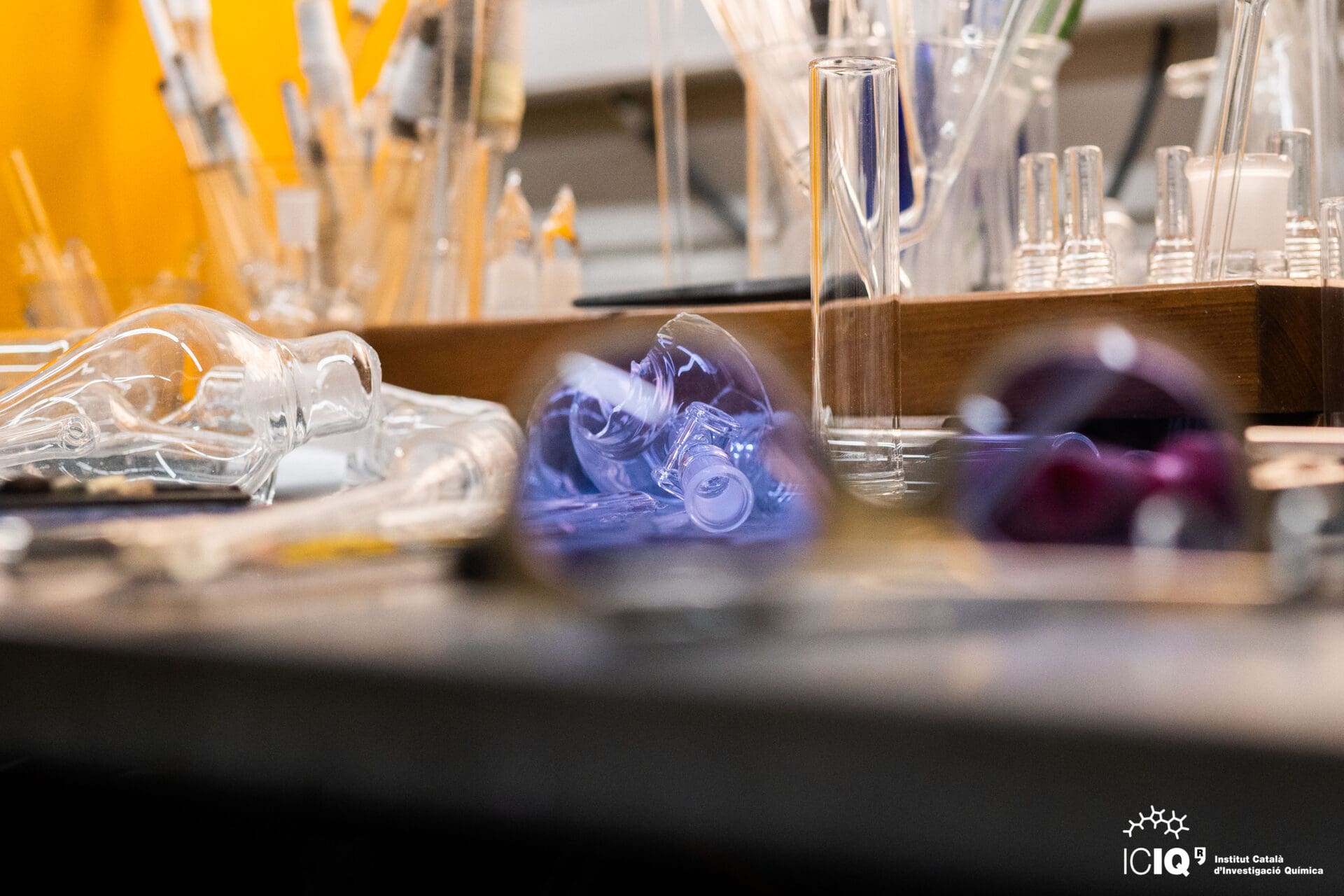

Reactors, funnels, cells, flasks, Friedrichs condensers and much more. The ICIQ Glass Blowing Workshop provides expertise in creating customized glassware for various chemical procedures. Xavier Asensio, who leads the unit, has been glassblower all his life. He specializes in chemical glassware, possessing high expertise in its design, fabrication and repair

The Workshop’s key strength lies in its ability to create unique glassware that is not available in the market. Companies can present a problem to the unit, and the team leads a project to design improvements on existing glassware, or a completely new glassware, to meet the objectives of the industrial process. “We create new objects with enhanced functions to turn any research procedure into a reality”, states Asensio. The Glass Blowing Workshop is equipped with three blowing torches, two furnaces, two saws and a polisher.

There is also the possibility of developing joint projects between the Mechanical and Glass Blowing Workshops. The units often collaborate to find more efficient solutions to industrial and laboratory problems. They are open to initiating new collaborations with extern partners to continue growing and achieve better results.

Related news

Let's create a brighter future

Join our team to work with renowned researchers, tackle groundbreaking

projects and contribute to meaningful scientific advancements

17-12-2024

17-12-2024