ICIQ – Innovation & Valorisation Laboratory

Building bridges between academia and industry

Since 2010, the Innovation and Valorisation Laboratory of ICIQ has been committed to bring science to market, hence contributing to the creation of a knowledge-based economy.

The Innovation and Valorisation Laboratory of ICIQ carries out the transfer of knowledge and technology to society through two main strategies:

- Support to companies towards product or process innovation with cutting-edge technologies.

- Valorisation to enable commercialisation of ICIQ’s own technologies, where the unit serves as a springboard to bring fundamental research into the market.

Along the years, the Innovation and Valorisation Laboratory of ICIQ has acquired a great experience in the broad field of chemistry thanks to its numerous collaborations with key national and international pharmaceutical, agrochemical and material companies, as well as its partnerships with scientific institutions in chemistry, biology or medicine, among others. On the other side, the Innovation and Valorisation Laboratory of ICIQ has successfully participated in the scientific development of some ICIQ’s cutting-edge technologies by incubating the ICIQ spin-off companies to ensure their success.

Focusing on ICIQ’s main research lines, its multidisciplinary team offers a wide expertise to accompany both academic groups and actors from the public or private sector in their pathway to innovation.

If you are facing difficulties in the development of your projects, if you want to scale-up a process, or if you need assistance for your technology to reach the market, the Innovation and Valorisation Laboratory of ICIQ will be the ideal platform to fulfil your objectives.

Expertise

Applied statistics dealing with planning, conducting and analyzing a limited number of experiments so as to evaluate the parameters that would influence the outcome of the reactions for further optimization.

Execution of a large numbers of experiments conducted in parallel. Combined with UPLC analysis, reaction conditions can be quickly optimized and allows obtaining libraries of compounds.

Vibratory or planetary ball mills allow a fine grinding and mixing of solid chemical entities that can initiate chemical reactions by mechanical phenomena for new studies on products formation.

Original and efficient multi-step synthesis of small molecules and natural products using enantioselective catalysis for the construction of chiral centers.

Discovery of new reactions thanks to visible or ultraviolet light that can have a potent effect on chemical reactions and induce reactivities that are not possible under thermal conditions.

In order to find new sustainable materials, our lab develops innovative polymers from biosourced monomers and possesses its own GPC equipment for analysis.

Development and optimization of production processes as well as the scale-up of reactions in a way that will mimic the production at a plant e.g., without using column chromatography for purification, telescoping of steps, azeotropic removal of water, increase reaction concentration, purging experiments, etc.

Depending on the amount, from mg to kg, molecules synthesized at the lab are purified using various strategies: column chromatography, crystallization, distillation, acid-base washing, etc.

Highlighted projects and publications

-

2022 | ChemSusChem

A Biosourced Epoxy Resin for Adhesive Thermoset Applications

Moreira, V. B.; Alemán, C.; Rintjema, J.; Bravo, F.; Kleij, A. W.; Armelin, E.

-

2023 | Angew. Chem. Int. Ed

Bicyclic Guanidine Promoted Mechanistically Divergent Depolymerization and Recycling of a Biobased Polycarbonate

Lamparelli, D. H.; Villar-Yanez, A.; Dittrich, L.; Rintjema, J.; Bravo, F.; Bo, C.; Kleij, A. W.

-

2017 | Adv. Synth. Catal.

cis-4-Alkoxydialkyl- and cis-4-Alkoxydiarylprolinol Organocatalysts: High Throughput Experimentation (HTE)-Based and Design of Experiments (DoE)-Guided Development of a Highly Enantioselective aza-Michael Addition of Cyclic Imides to α,β-Unsaturated Aldehydes

I. Arenas, A. Ferrali, C. Rodriguez-Escrich, F. Bravo, M.A. Pericàs

-

2021 | Org. Lett. 2021, 23, 6429-6434

Deciphering the Keys for High Enantioselectivity in Hypervalent Iodine-Catalyzed 1,2-Difunctionalization: Improved Synthesis of Ishihara–Muñiz PrecatalystsClick to copy article link

Equipment

-

Aapptec Focus XC Peptide synthesizer

Polypeptides are easily synthesized thanks to this fully automated apparatus.

-

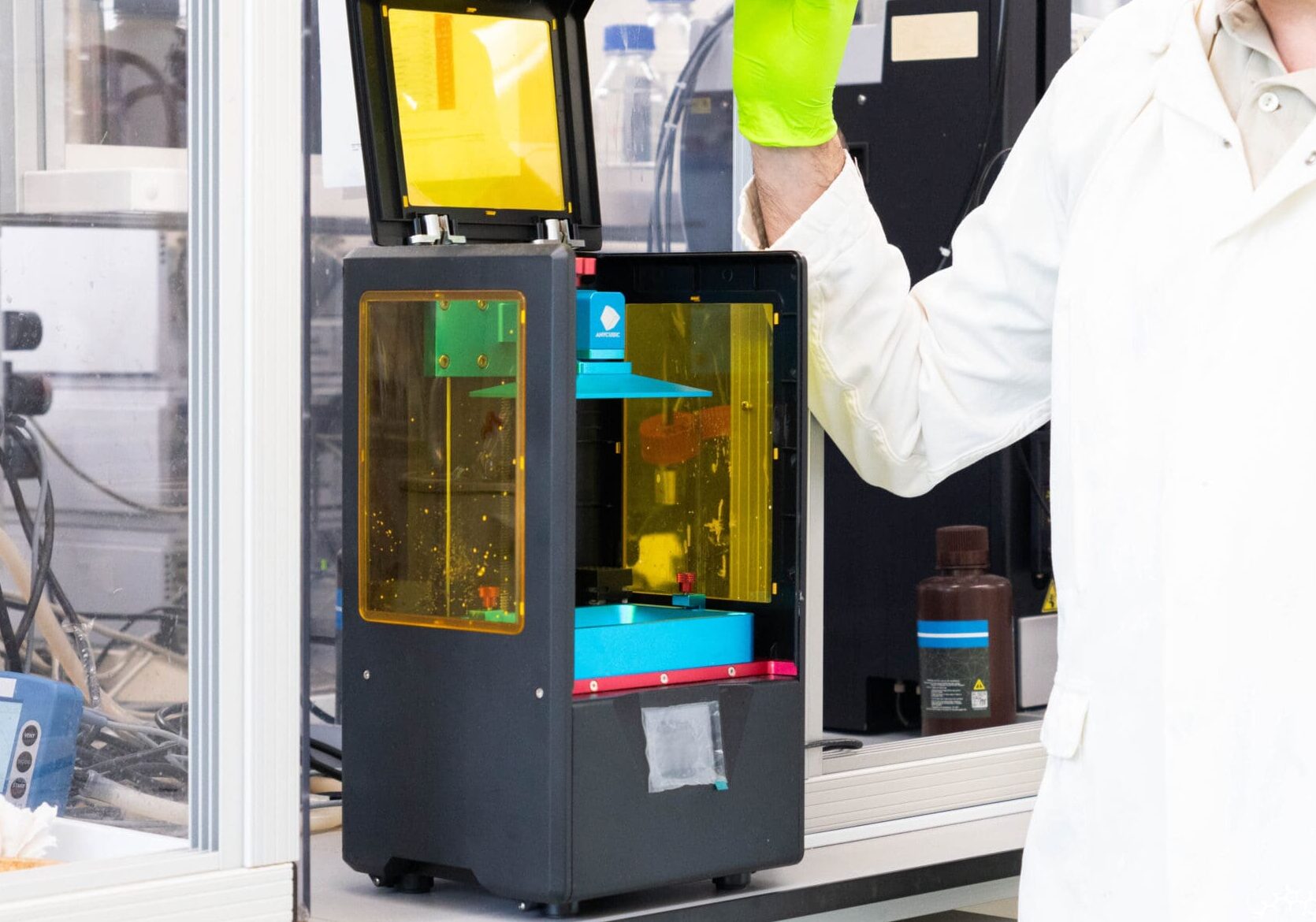

Anycubic Photon S 3D Printer

With such printer, new photopolymerization formulations can be optimized. It also allows to design devices for various applications such as heterogeneous catalysis or gas separation.

-

Biostat potentiostat

Electrochemical reactions can be finely tuned with such item that allows to regulate the required current for specific reactions.

-

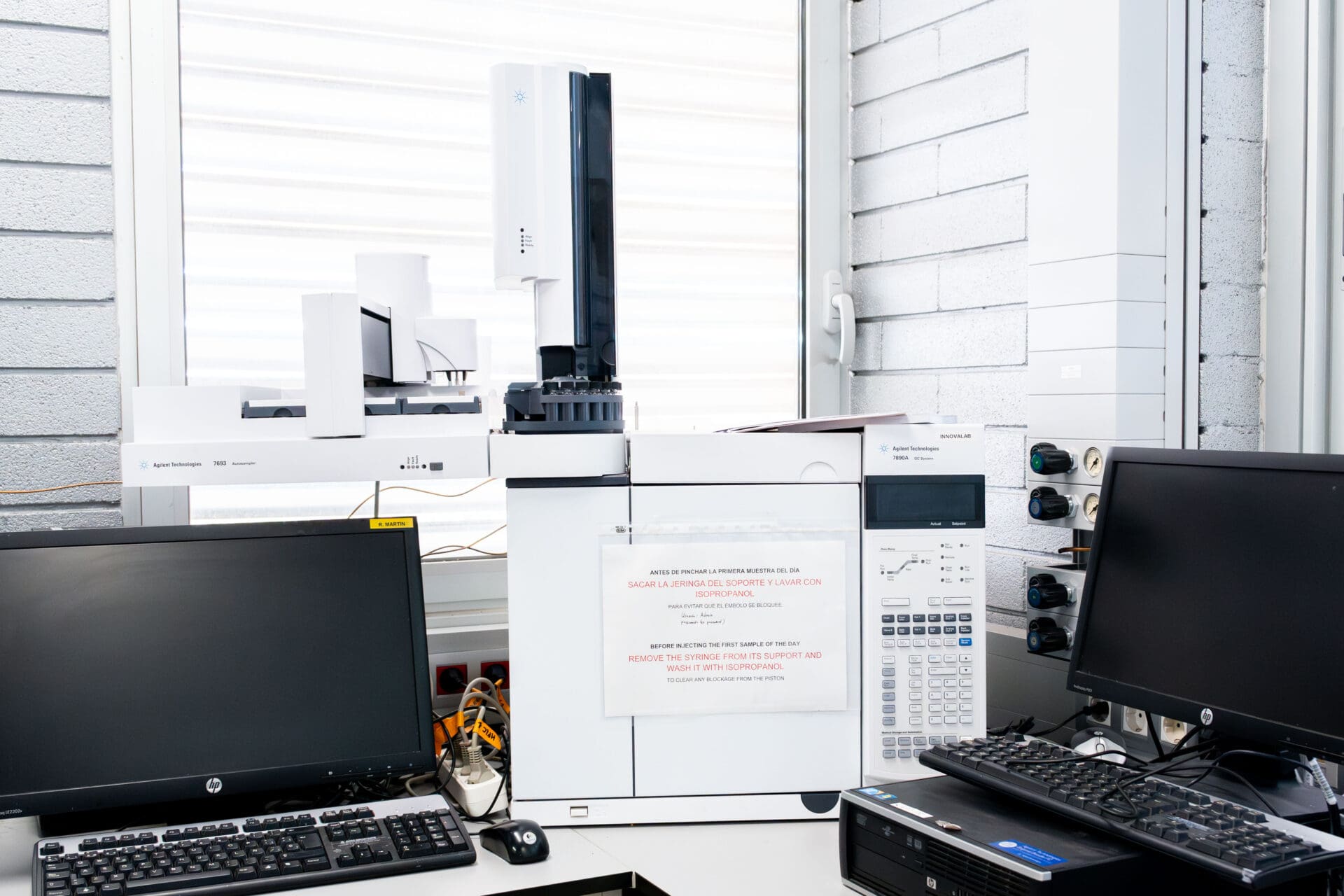

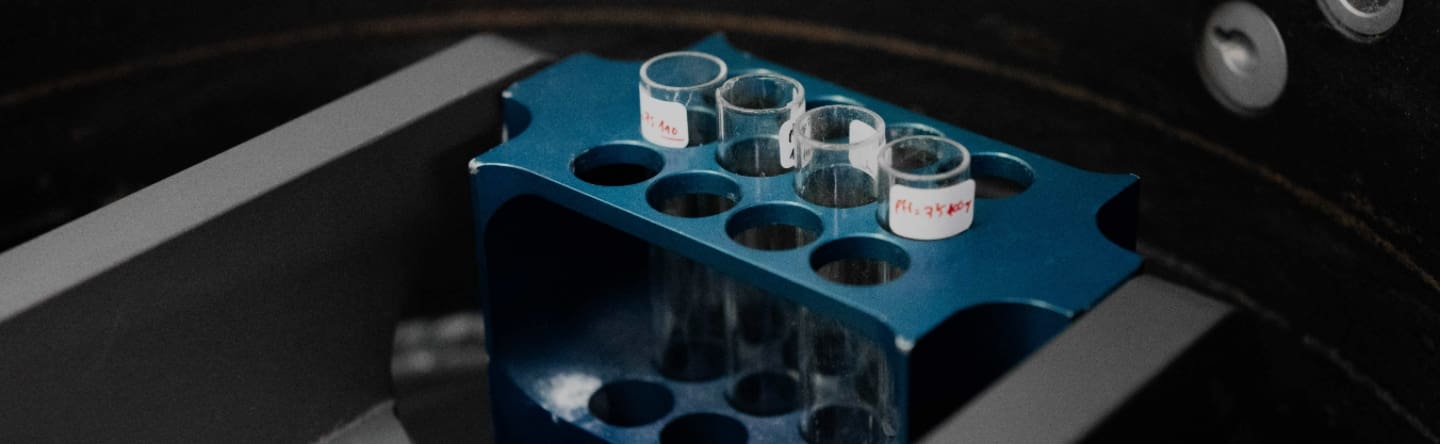

Gas Chromatography (GC) Agilent 7890A with Autosampler 7693

As a complement to HPLC, GC allows the separation and detection of more volatile compounds.

-

Gel Permeation Chromatography (GPC) Agilent 1200 Series

GPC allows to determine key characteristics of large molecular weight compounds such as polymers or oligomers.

-

High-Pressure Liquid Chromatography (HPLC) Agilent Infinity 1260 + Quadrupole LC/MS 6130

HPLC-MS allows a daily routine follow-up of experiments as well as it can be used for purity determination. Thanks to this technique, separation of compounds mixture as well as determination of chemical structures are facilitated.

-

LEDs for light irradiation with several wavelengths

Photochemical reactions required specific wavelengths. Thanks to our various available lights, processes can be optimised to develop reactions with uncommon reactivity compared to classical thermic conditions.

-

MBraun LabMaster SP Glovebox

In order to store moisture and air-sensitive reagents but also to prepare or even carry out reactions under inert atmosphere, our lab possesses its own glovebox, available at all time.

-

Mettler-Toledo EasyMax 102

This equipment mimics industrial reactors on a small scale (few grams) and thus gives hints for optimising the process development of molecules such as pharmaceutical ingredients.

-

Mettler-Toledo Volumetric Karl-Fischer Titrator V10S

This volumetric titrator allows to determine water amounts in solid or liquid samples.

-

Teledyne Isco Combiflash Rf200 (x3)

These automated purification systems allow easier and quicker isolations of pure organic compounds.

Events

-

April 2025

04

Nanocapsules as Nanocarriers for Targeted Drug Delivery and as Modules for Synthetic Cells

-

April 2025

09

PhD ThesisInsights into the Stability of Single-Atom Catalysts on Doped Carbon Using Machine Learning Techniques

-

May 2025

16

SeminarApproaches and Catalyst’s Designs in Anion-Binding and Acridinium Photocatalysis

-

June 2025

10

SeminarTitle to be announced

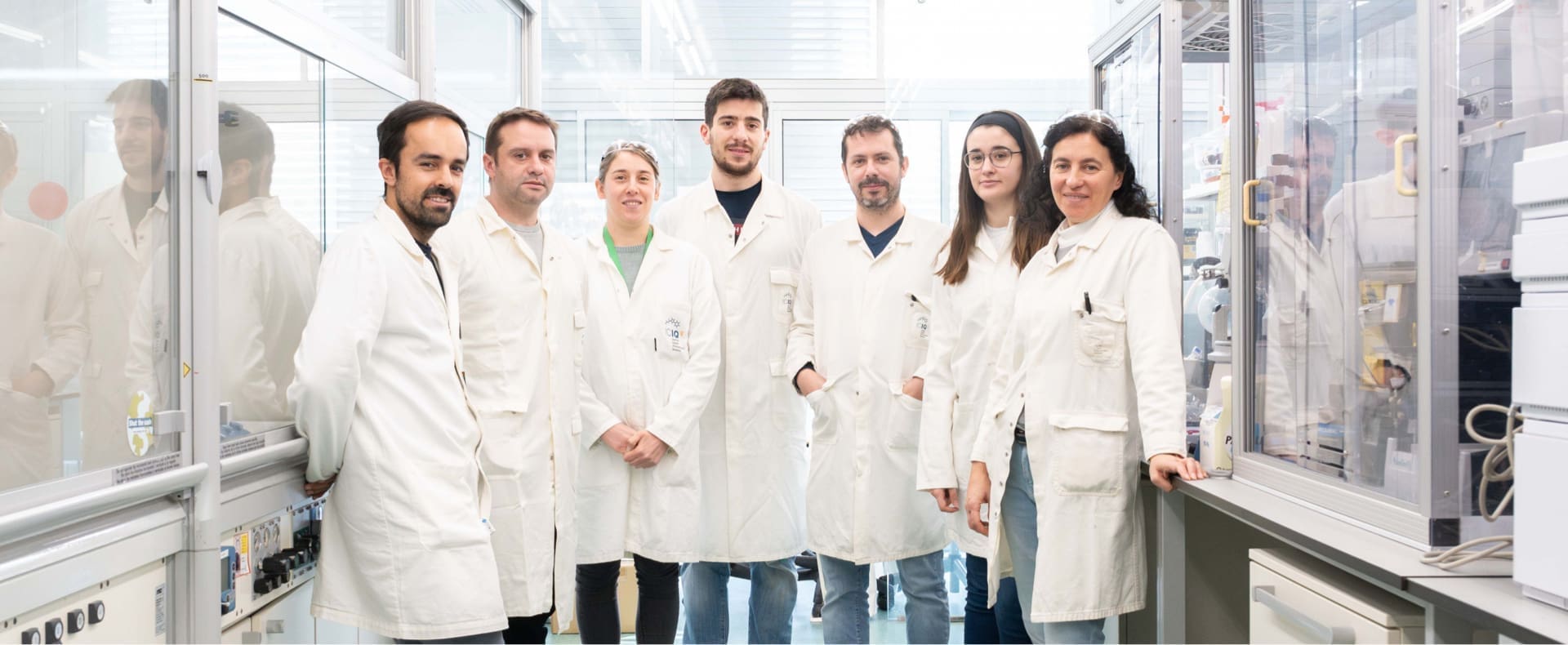

Innovation and Valorisation Laboratory Team

Get started with an expert

Together, let’s create a brighter future providing solutions through a partnership

Connect with us