Chemical Reaction Technologies

Technical support in chemical reaction development, specially in reaction parallelization and high throughput synthesis, reaction scale-out, in situ reaction monitoring, high pressure reactions and reactions performed in microflow reactors.

About

The Chemical Reaction Technologies Unit provides ICIQ researchers with technical support in chemical reaction development, specially in reaction parallelization and high throughput synthesis, reaction scale-out, in situ reaction monitoring, high pressure reactions and reactions performed in microflow reactors.

In the field of chemical parallelization, the unit has equipment to perform all the unit operations involved in a chemical process: reaction, work-up, purification and final isolation of the product.

A chemical reaction can be scaled up in a fully computer controlled reactor, from 0.6 to 6 L. This scale is optimal for preparing in-house starting materials and for technology transfer in cooperation projects.

In situ reaction monitoring can be performed by FTIR and NMR using the HPIR reactor, the HPNMR tube or Polychrome V. These techniques are non-intrusive and are very useful for kinetic and mechanistic studies.

Moreover the unit provides ICIQ researchers with different technologies to perform reactions under singular conditions such as a microwave reactor, a photochemical reactor and a set of flow reactions. In this sense, the unit also offers access to a clean room (ISO 7) and a laboratory specially designed to run reactions under pressure conditions.

Equipment

-

Supercritical CO2 reactor

Reactor to work with supercritical CO2 from SITEC equipped with windows, with a reaction volume of 30mL and the capability to work up to 400bar and 200ºC.

-

Ball mill

A ball mill MM200 from Retsch with sample vessels of 1, 5 and 25 mL.

-

Clean Room

Class 7 45 m2 clean room. Equipped with standard facilities in ICIQ laboratories: fume hoods, safety cabinet, nitrogen, argon, compressed air, exhaust points, cooling water and vacuum (1*10-2mbar).

-

Low pressure reactors

A low pressure reactor (4 bar) from Parr, with shaker stirring, and glass reaction vessels with volumes from 4 to 500 mL.

-

Liquid phase parallel chemical synthesizer

A computer controlled, liquid phase parallel chemical synthesizer from Mettler Toledo with four reactors of 50 mL, mechanical stirring and independent internal and external temperature control for each reactor. Reactions can be performed between -30 and 180 ºC, with the possibility to automatically adding liquid reagents and taking samples which will be collected in HPLC /GC vials.

-

Laboratory chemical reactor

A computer controlled laboratory chemical reactor, LabMax from Mettler Toledo. It can adapt reactors of 0.6, 2.0 and 6.0 liters, and has the capability to measure and control reaction temperature (from -30 to +230 ºC), pH, stirring speed (from 30 to 2500 rpm) and liquid additions. It can work under reflux, distillation, under vacuum or inert atmosphere.

-

HPIR Reactor

A special reactor to monitor pressure reactions in situ, by FTIR. It can go up to 120 bar at high temperature (maximum 150 ºC).

-

HPNMR tube

NMR tube to perform NMR measurements under high pressure conditions (1 bar to 200 bar). The maximum working temperature is 150ºC.

-

High pressure reactors

Two high pressure Hastelloy reactors: a 100 mL mechanically stirred reactor (0-3000 rpm) with the possibility of adding reactants or taking samples manually, and a 25 mL magnetically stirred reactor. Both reactors can work at temperatures between 25 and 200 ºC (internal temperature) and to a pressure of 68 bar at 25 ºC and 200 bar at high temperature. Stainless steel high pressure reactors with a capacity of 25, 40, 75, 100, 150, 300 and 1000 mL, and the possibility to work up to 180 ºC and 200 bar at high temperature. They offer the possibility of taking samples manually.

-

Metal and organic molecule evaporator

System composed by an MBraun inert gas glove box, which includes a high vacuum chamber (1×10-6 mbar) with four electro-thermal sources for metal and organic molecules evaporation. This system allows the control of film thickness from 5 up to 300 nm.

-

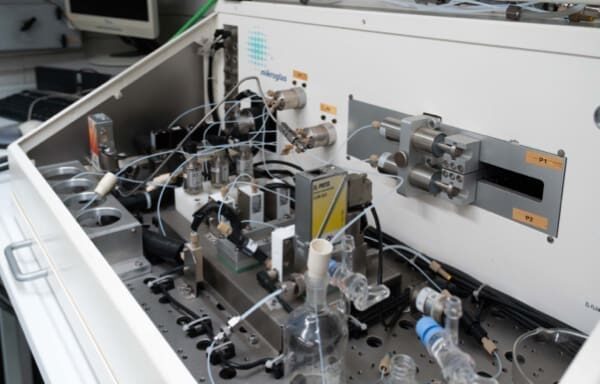

Microreactors

Four Microsystems are available: two systems for homogeneous liquid-liquid reactions, one equipment for simple reactions and one for cascade or consecutive reactions. One for heterogeneous solid-liquid reactions. And one for high pressure gas-liquid reactions (up to 20 bar).

-

Microwave reactors

A microwave reactor CEM Explorer equipped with a 24 position autosampler. It has the capacity to work up to 300 ºC, with working volumes from 0.5 to 7 mL in a closed tube, up to a pressure of 21 bar, and from 1 to 100 mL in an open reactor. Biotage Initiator system can process reaction volumes between 0.2 ml and 20 ml. It has the capacity to work in a temperature range between 40 ºC and 250 ºC and under pressures of up to 20 bar.

-

Ozone generator

A laboratory ozone generator CMG 5-5 from INNOVATEC.

-

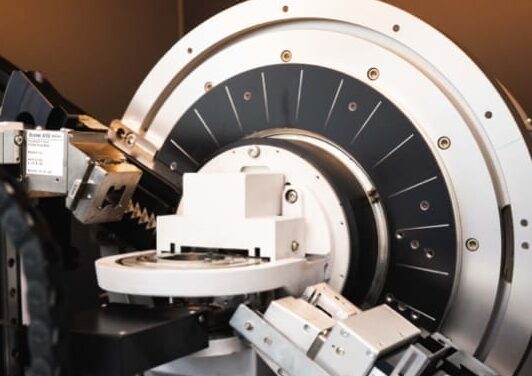

Parallel pressure chemical synthesizer

A computer controlled, parallel pressure chemical synthesizer SPR-16 from Amtec. The equipment has 16 reactors of 9 mL with independent control of temperature (25-250 ºC), stirring speed (30-2000 rpm) and pressure (1-100 bar at room temperature up to 130 bar at high temperature). It has the possibility to add liquid reagents and to automatically take samples.

-

Photochemical reactor

A photochemical reactor Rayonet RPR-200 with lamps at 254, 300 and 350 nm and reactors with a capacity of 10 and 150 mL.

-

MiniBlocks

Reaction blocks of different configurations (12 x 14 mL, 24 x 7 mL and 6 x 40mL) adapted to work in a conventional stirring plate, working temperatures between -20 and 120 ºC.

-

Sample Storage System

The system allows you to keep samples at -40ºC in coded 1mL glass vials sealed with septum. There is space to store 43200 samples organized in racks, trays and boxes. The samples are managed through a database (e-notebook), where each compound can be described.

-

Preparative flash chromatography system

A preparative flash chromatography system, Combiflash from Teledyne ISCO, with UV detector and the capacity to adapt silica columns from 4 to 330 g.

-

Polychrome V

Polychrome V from Till Photonics is a monochromatic light source (150W Xenon high stability lamp Tilluxe P45) with an optical fibre connected to the outlet to lead the light to the desired target. The wavelength delivered (320-680 nm) is controlled from a computer. The bandwidth and intensity of the light can be adjusted.

-

H-Cube ProTM

The H-Cube Pro™ system is based on the hydrogenation of a continuous flow of reactant. Additional equipment, HPLC pump, is needed to introduce the reactant into the H-Cube Pro™ device, where the solution of reactant is mixed with the in-situ generated hydrogen.

Staff

Other research units

Let's create a brighter future

Join our team to work with renowned researchers, tackle groundbreaking

projects and contribute to meaningful scientific advancements