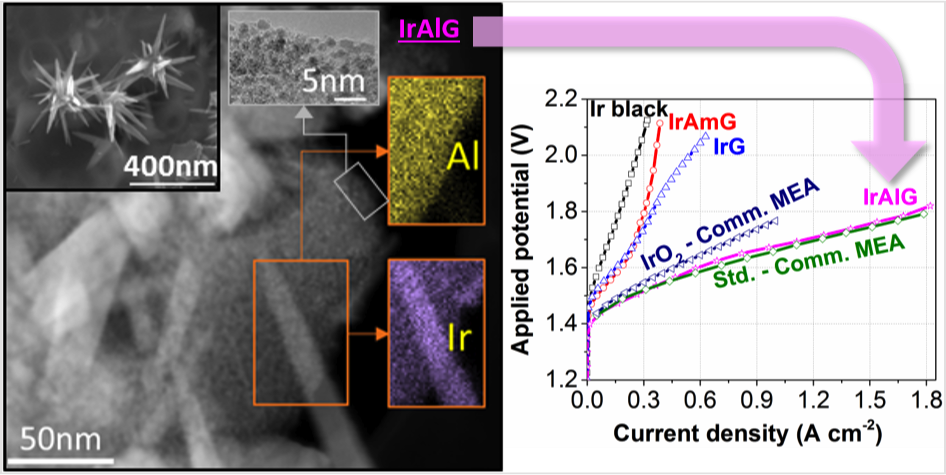

Iridium based materials are the state-of-the-art anode catalysts for polymer electrolyte membrane (PEM) water electrolysis thanks to their unmatched stability and performance in the acidic environment of common PEMs like Nafion®. However, their uses on a large-scale operation are cost-restrictive. To improve their wider utilization, identifying a synthesis method of nano-structured iridium oxide with high dispersion and high active surface area is of great importance. For this aim, we developed a one-step and cost effective solution combustion synthesis (SCS) method to prepare nano-structured IrO2 and IrO2-based materials suitable for PEM electrolysis. Among various materials prepared, the iridium oxide incorporated and dispersed in amorphous alumina showed high surface area (131 m2 g-1) and the current density of 1.78 A cm-2 at 1.8 V which is comparable to the performance of the state-of-the-art commercial MEA made of IrRuOx (1.8 A cm-2 at 1.8 V) under PEM water electrolysis. Importantly, the dispersion of the material in the catalyst ink used for the preparation of membrane electrode assembly (MEA) was significantly superior compared to commercial IrO2 nanoparticles and the amount of the precious metal in the catalyst made by SCS could be reduced by 45 wt% compared to that in the commercial MEA.