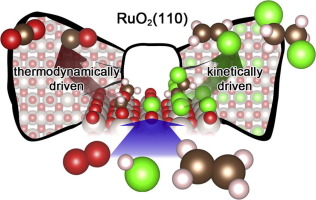

The oxychlorination of ethylene is an industrially relevant process within the manufacture of polyvinyl chloride (PVC). Although RuO2 is the best performing catalyst for the Deacon process (4HCl + O2 → 2H2O + 2Cl2), experiments demonstrate a modest activity in the selective oxychlorination to vinyl chloride, favouring oxidation and polychlorinated saturated products. From the computational modelling three main contributions are found to control the performance: (i) coverage effects that alter the configuration of intermediates; (ii) the monodimensional arrangement of the active sites, in which the reaction of coadsorbed species works on a “first-come, first-served” basis; and (iii) the high reactivity of the oxygen species. Competition between oxidation and chlorination processes results in variable selectivity, depending on the reaction conditions (particularly temperature and reactant partial pressures), which influence the surface composition. From the analysis of the complex reaction network, the essential requirements for a good oxychlorination catalyst are formulated.