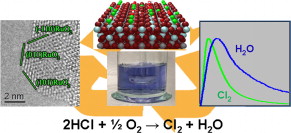

Rationally designed RuO2-based Deacon catalysts can contribute to massive energy saving compared to the current electrolysis process in chemically recycling HCl to produce molecular chlorine. Here, we report on our integrated approach between state-of-the-art experiments and calculations. The aim is to understand industrial Deacon catalyst in its realistic surface state and to derive mechanistic insights into this sustainable reaction. We show that the practically relevant RuO2/SnO2 consists of two major RuO2 morphologies, namely 2-4 nm-sized particles and 1-3-ML-thick epitaxial RuO2 films attached to the SnO2 support particles. A large fraction of the small nanoparticles expose {1 1 0} and {1 0 1} facets, whereas the film grows with the same orientations, due to the preferential surface orientation of the rutile-type support. Steady-state Deacon kinetics indicate a medium-to-strong positive effect of the partial pressures of reactants and deep inhibition by both water and chlorine products. Temporal Analysis of Products and in situ Prompt Gamma Activation Analysis strongly suggest a Langmuir-Hinshelwood mechanism and that adsorbed Cl poisons the surface. Under relevant operation conditions, the reactivity is proportional to the coverage of a specific atomic oxygen species. On the extensively chlorinated surface that can be described as surface oxy-chloride, oxygen activation is the rate-determining step. DFT-based micro-kinetic modeling reproduced all experimental observations and additionally suggested that the reaction is structure sensitive. Out of the investigated models, the 2 ML RuO2 film-covered SnO2 gives rise to significantly higher reactivity than the (1 0 1) surface, whereas the 1 ML film seems to be inactive.